If you want to make sure that your labels adhere to bottles and jars perfectly, CTM Labeling Systems are an excellent option. These machines are portable, which makes them perfect for small breweries and wineries. They have both single and dual-label applications. In addition to printing labels, they also pack pallet boxes, so you can easily ship your finished products to your customers. One commercial label applicator can apply up to 1000 bottles per hour, which is more than enough to produce eight thousand bottles in a day. Hence, a single person can produce ten pallets of wine in an eight-hour shift.

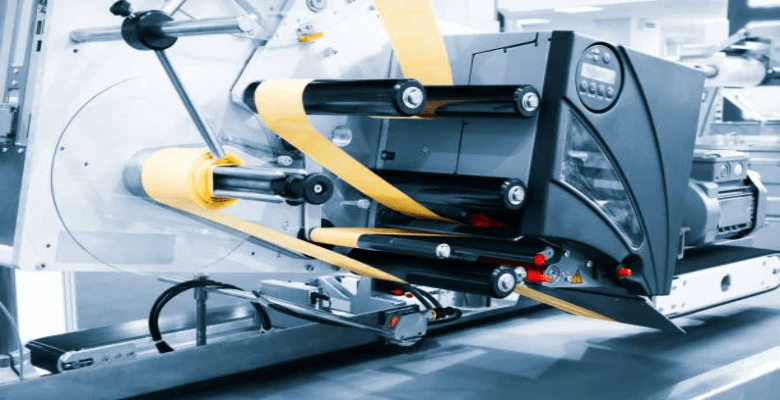

Another type of commercial label applicator is the corner wrap style. It works by applying the labels to the corners of the package using a dual-action vacuum tamp pad. A corner wrap label applicator has a cylinder that elongates toward the product as it passes by the pad. A corner wrap label applicator will roll around the corner of the package, ensuring a firm attachment. In addition to these two types of applicators, there is the print-and-apply system. Print applicators are made for rugged use, and they use an O.E.M. print engine to apply labels to a product.

A standalone label applicator is another type of commercial label applicator. This type of applicator can be integrated with a product handling system and can include a portable head mount. Alternatively, it can be installed on a conveyor or other machine. Wipe-on labeling is the most common pressure-sensitive labeling method. A brush or roller applies the label to the product as it passes the applicator's dispense edge. This type of commercial label applicator fits on the Label-Aire 5100 series, and is compatible with the Label-Aire model 3115-NV Wipe-On Primary Applicator.

Another type of commercial label applicator is the Alpha HSM. This is a high-speed label applicator that features an advanced dual microprocessor system. A single 32-bit processor controls the application program, while a digital signal processor supervises the motion loop. Both the microprocessors provide high-quality performance and accuracy. They can even be customized to meet the unique needs of the customer. You can choose from a wide range of models that can suit your requirements.

If you are looking for a commercial label applicator, you can consult a CTM Labeling videojet. A Videojet sales engineer can evaluate your unique needs and determine the most cost-effective solution. Videojet's Intelligent Motion technology helps reduce the top 5 reasons for labeling machine downtime. It also eliminates 80% of wear parts, reducing labor and set-up time. These machines can achieve 150ppm for a typical four-by-six label.

Another type of commercial label applicator is the automatic hot melt glue labeling machine. The automatic model is highly versatile and can be used to label different types of bottles. It is also very inexpensive and suitable for mass production. This type has a modular design concept, which allows it to handle different types of containers. Commercial self-adhesive label applicators are also designed to fit any shaped bottle, including round bottles, folded corners, and bags.

Keep reading on https://en.wikipedia.org/wiki/Labelling and most importantly, convert your knowledge into action, otherwise it remains a source of untapped energy as well as wasted potential.